Номер международной заявки: PCT/RU2010/000196

Заявитель - автор: ЧЕТВЕРИКОВ Александр Валерьевич

Международная патентная классификация (МПК): B63B 7/06 (2006.01), B63B 35/71 (2006.01)

Дата международной публикации: 25.11.2010

Приоритет от 19.05.2009 по заявке EA 200900763FOLDING KAYAK

Field of applicationThe invention relates to small vessels construction, particularly to a folding kayak. Kayak is a type of one-man row boat. The archetype is a boat which was widespread among peoples of the North. Modern kayaks are used for rapid and vast waters navigation, Whitewater, water rodeo (free style), rafting, water activities, expeditions. There is used two-bladed paddle to propel a kayak. Seat of a kayak's occupant is covered with special waterproof material to exclude water fixed on a coaming around a cockpit occupied by a kayaker.

Background of inventionThere is known a folding kayak consisting of a hull made of flexible bicurved shell, which edges are fastened at deck zone and conform to rigid part having a cockpit for a kayaks 's occupant with a coaming around it. Bow and stern of the hull are sealed by outer casings. In the outer casings portion there are plugs. The plugs and outer casings are tightened to each other. Bottom ceiling is located within the hull and it consists of central part, extending bow and stern parts and side parts secured to the coaming. The bottom ceiling provides the hull with strength and rigidity required. The central part of the bottom ceiling positioned at the hull bottom opposite the cockpit is intended for a kayaker (RU 2283258 C2, IPC B63B 7/06 (2006.01), 2006).

The flexible shell, as expressed above, forms major part of the kayak's hull surface. To connect and tighten longitudinal joints of the flexible shell disposed on the deck there are applied lining triple-slotted clamps. The clamp consists of a frame with longitudinal grooves, wherein flexible shell edges with shoulders are inserted, and two expanders by shift of which grooves tighten thereby fixing the flexible shell edges. The coaming is made collapsible with quick-release connections of its parts with each other, cover and triple-slotted clamps.

It complicates manufacture of the flexible shell since it is equipped with the shoulders. Besides it makes it difficult to roll up. There are required several triple-slotted clamps of complex form for its assembling. The construction envisages the bottom ceiling of complex branched structure.

On the whole the known construction is characterized by plenty of complex details inadaptable to streamlined production, all have the difficulty to be packaged compactly.

Substance of inventionThe objective of the invention is to propose a simple design adaptable to streamlined production and which can be folded into a compact pack.

This objective can be achieved by a folding kayak containing bow and stern parts of a deck made with front and rear portions of a coaming, respectively; side portions of the coaming rigidly united with the front and rear portions of the coaming of the bow and stern parts of the deck forming a cockpit; a hull shaped by flexible shell which edges are fastened along side edges of the bow and stern parts of the deck and alongside on the side portions of the coaming; at least one seat for a kayk's occupant; bow and stern sealing joints for the hull cavity isolation; and inner flexible skin disposed within the hull, in the cockpit zone, at least, with its opposite sides secured to the side portions of the coaming.

In a preferred embodiment of the invention the inner flexible skin is made, at least, with two reinforcing longitudinal elements which are located along the hull at its bottom part.

In the preferred embodiment of the invention within the hull at its bottom part there are positioned stringers telescopically joined with the reinforcing elements of the inner flexible skin.

It is preferable to make the seat with hinged backrest; the seat is fixed on the reinforcing longitudinal elements of the inner flexible skin whereas the backrest is fixed on the side portions of the coaming. In an advantageous embodiment the folding kayak is provided with a foot rest, fixed at the stringers in the bow part of the deck; and pillar linked to the foot rest and bow part of the deck.

It is preferable to provide the side edges of the bow and stern parts of the deck and side portions of the coaming with conjugated grooves alongside where the hull's flexible shell edges fit into. In this specific embodiment the bow and stern parts of the deck and side portions of the coaming may have holes located transversely to the grooves, said holes coincide with those made at lateral edges of the hull's flexible shell. In this case clamping elements fixing the hull's flexible shell fit into the holes.

The folding kayak may have two flexible bands each of them containing clamping elements fixing the hull's flexible shell on one side. These elements may be produced as L-shaped extensions, the ends of which are parallel to the flexible band and are directed towards its centre. The flexible bands may have arc-shaped end clamping elements at their ends, located on the same side of each band with the clamping elements in form of L-shaped extensions having their concave parts facing inwards.

Outer parts of the side edges of the bow and stern parts of the deck and side portions of the coaming can be provided with conjugated indentations alongside for the flexible bands location.

In the preferred embodiment of the invention each bow and stern sealing joint is made in the form of outer casing and a plug positioned within. Herewith the outer casing may have a hinged clamping lever in order to fix the flexible bands ends and to attach the outer casing to the bow or stern parts of the deck. The hinged clamping lever may be connected with a pusher situated within the outer casing to push the plug inwards. Each bow and stern part of the deck may be made of, at least, two coupled parts. The side portions of the coaming may be made as an integral unit with the inner flexible skin.

The hull's flexible shell and inner flexible skin, outer casings, plugs, bow and stern parts of the deck, as well as side portions of the coaming may be made of thermoplastic polymer material. The hull's flexible shell and inner flexible skin may be 1-2 mm thick and may be made of sheet polyethylene, polypropylene or ABS-resin.

The reinforcing longitudinal elements may be made in the form of hollow elements formed of inner flexible skin parts, the stringers may be molded of thermoplastic polymer material. The flexible bands may be produced in the form of flattened tube made of rubber or polyurethane.

Realization of inventionAn illustrative embodiment of the invention is shown in the accompanying drawings and described in detail below.

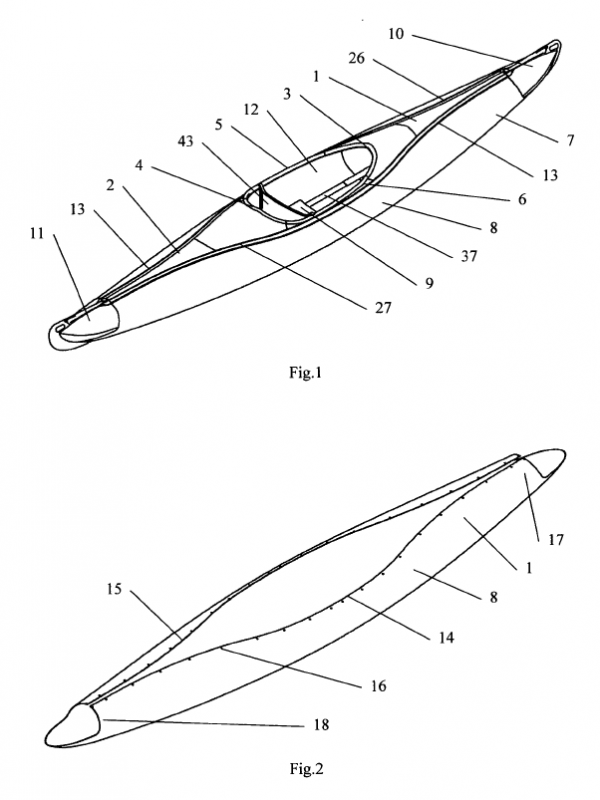

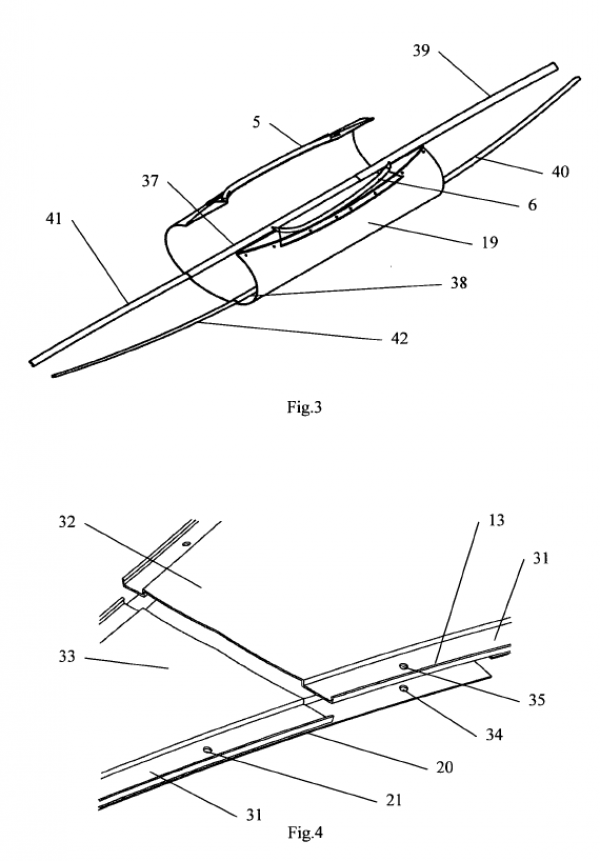

Fig. 1 is an overall three-dimensional view of a folding kayak, being an illustrative embodiment of the invention;

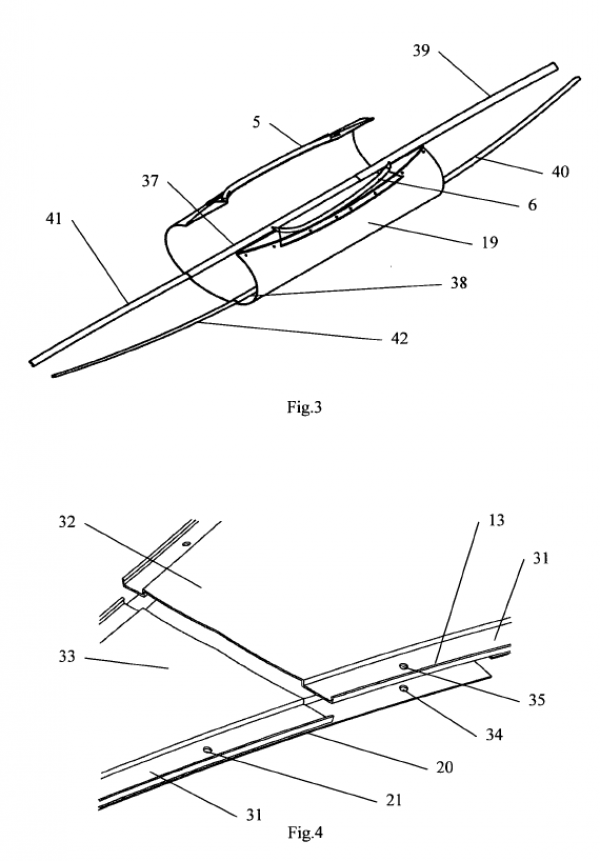

Fig. 2 is a three-dimensional view of flexible shell which is to constitute the hull wall of the kayak;

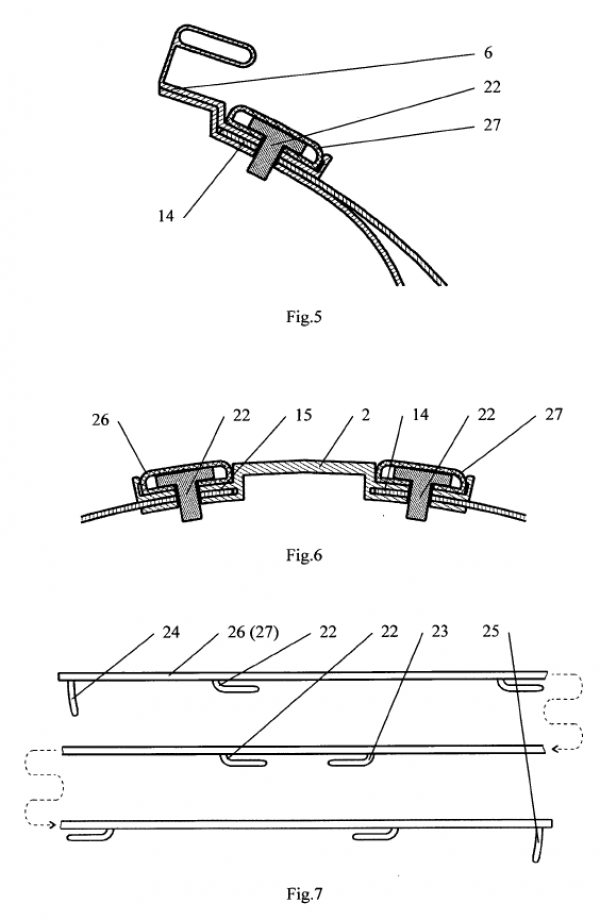

Fig.3 shows a fragmentary 3-D view of the folding kayak including inner flexible skin, side portions of the coaming and stringers; Fig. 4 illustrates conjugation of stern (bow) parts of the deck (they are shown apart for illustration purposes), 3-D view;

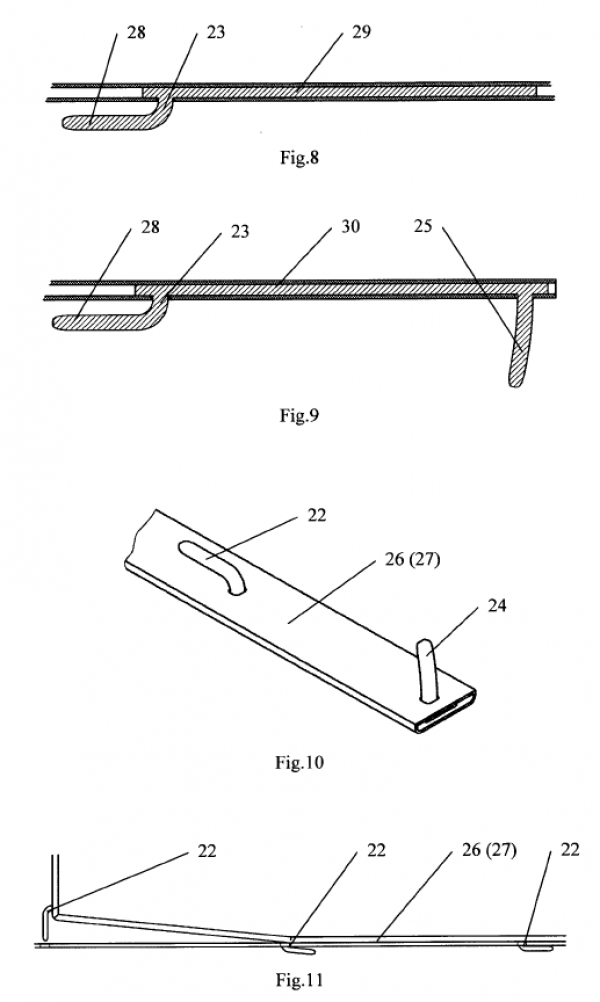

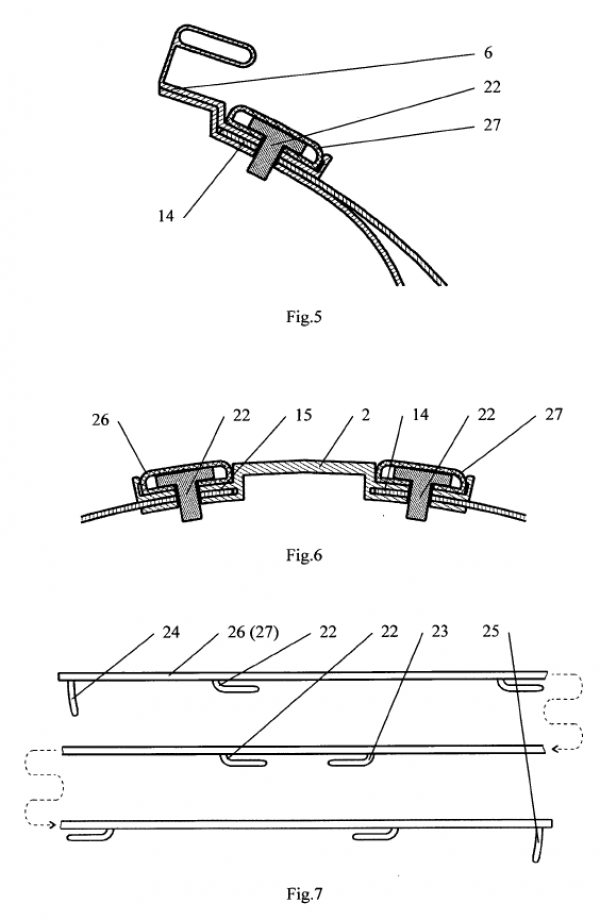

Fig. 5 is a cross-section of the side portion of the coaming with adjusted flexible band and fragments of the hull's flexible shell and inner flexible skin;

Fig. 6 is a cross-section of the bow (stern) part of the deck with the adjusted flexible bands and fragments of the fixed hull's flexible shell;

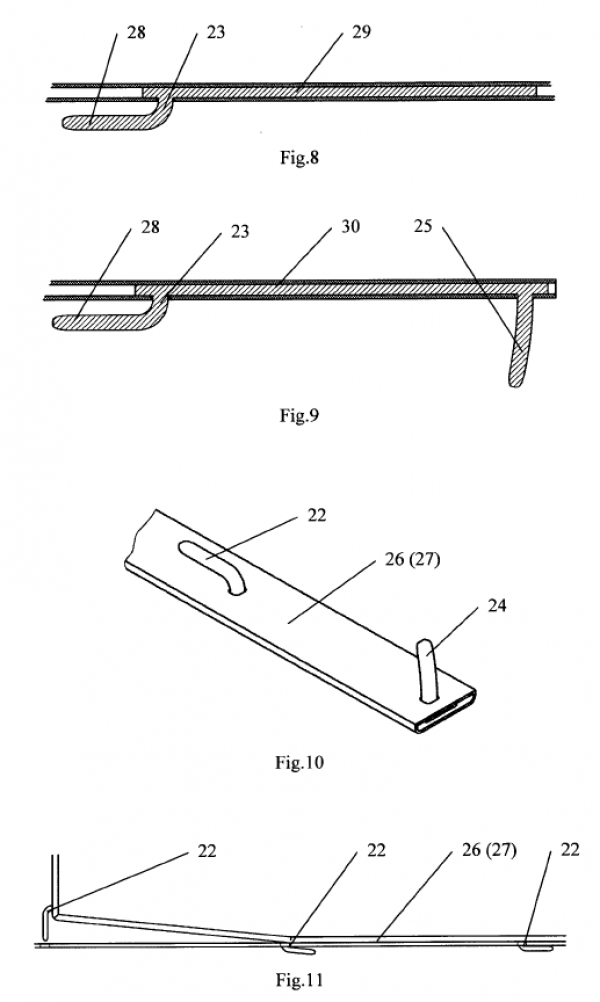

Fig. 7 is a lateral view of the flexible band with clamping elements;

Fig. 8 is a longitudinal sectional view of the flexible band piece in the zone of L-shaped clamping element;

Fig. 9 is a longitudinal sectional view of a fragment of the flexible band end;

Fig. 10 is a 3-D view of a fragment of the flexible band end as seen from the clamping element side;

Fig. 11 shows flexible band installation diagram;

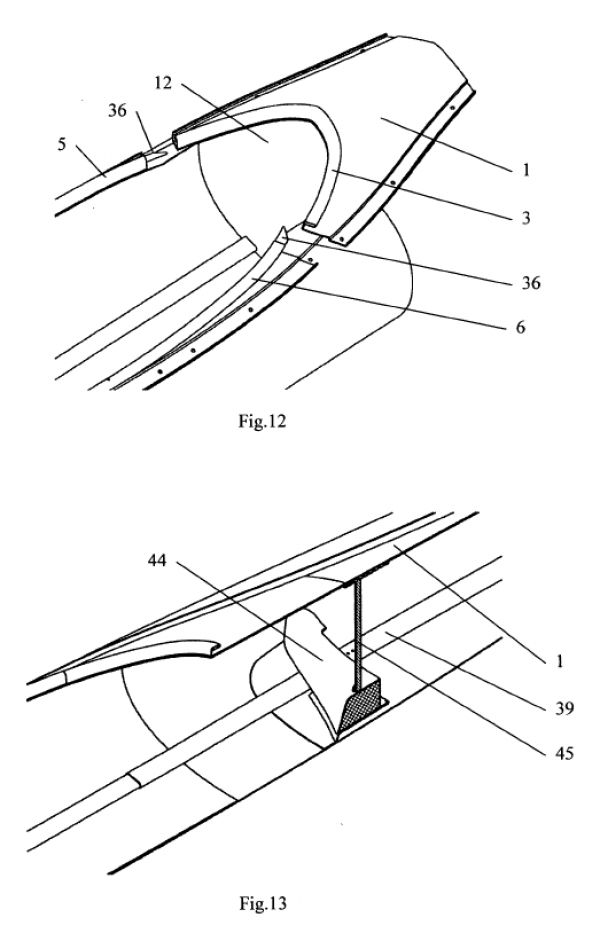

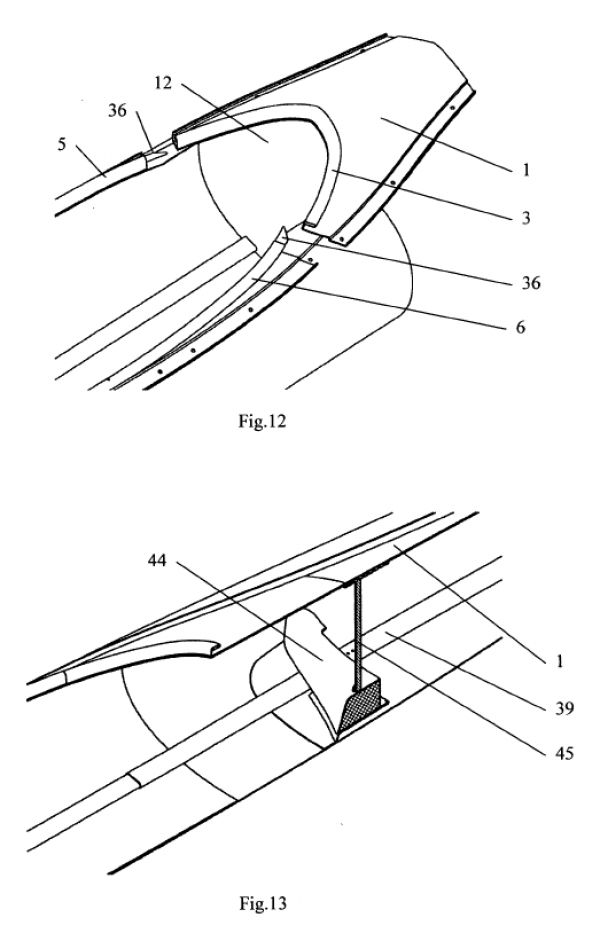

Fig. 12 is an exploded 3-D view of conjugation of the front part of the deck with the side portions of the coaming;

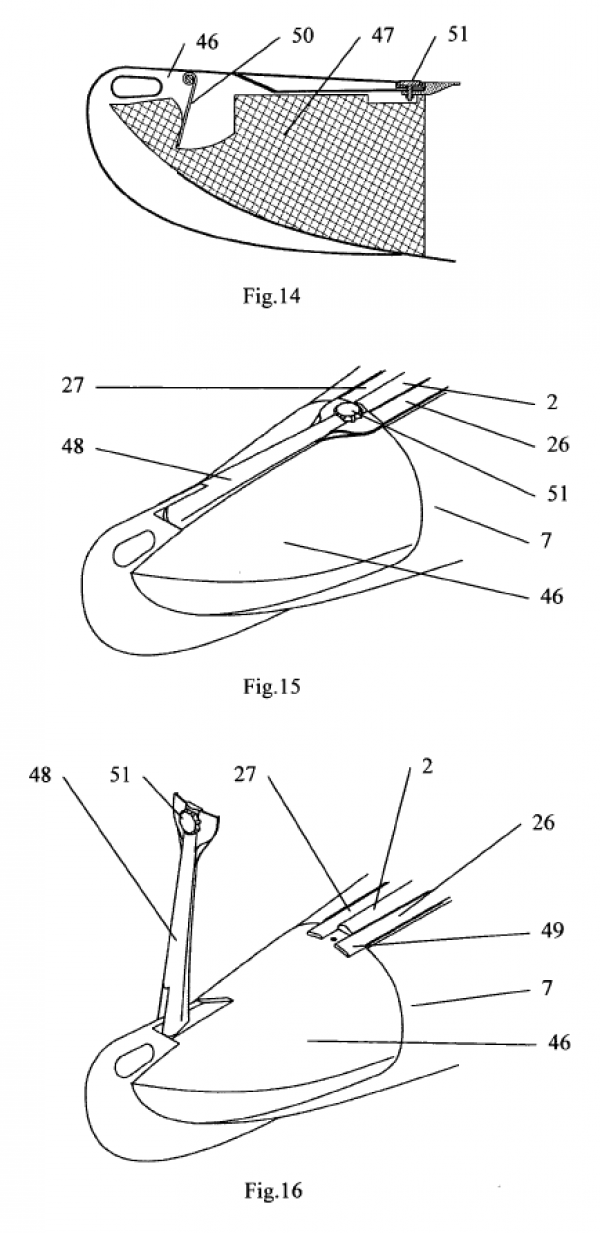

Fig. 13 is a longitudinal sectional view of the folding kayak fragment in the bow part of the deck;

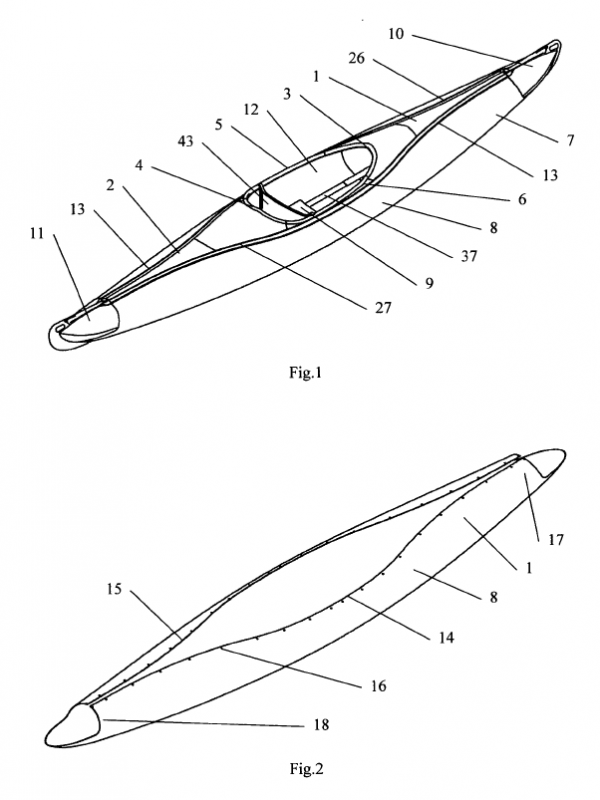

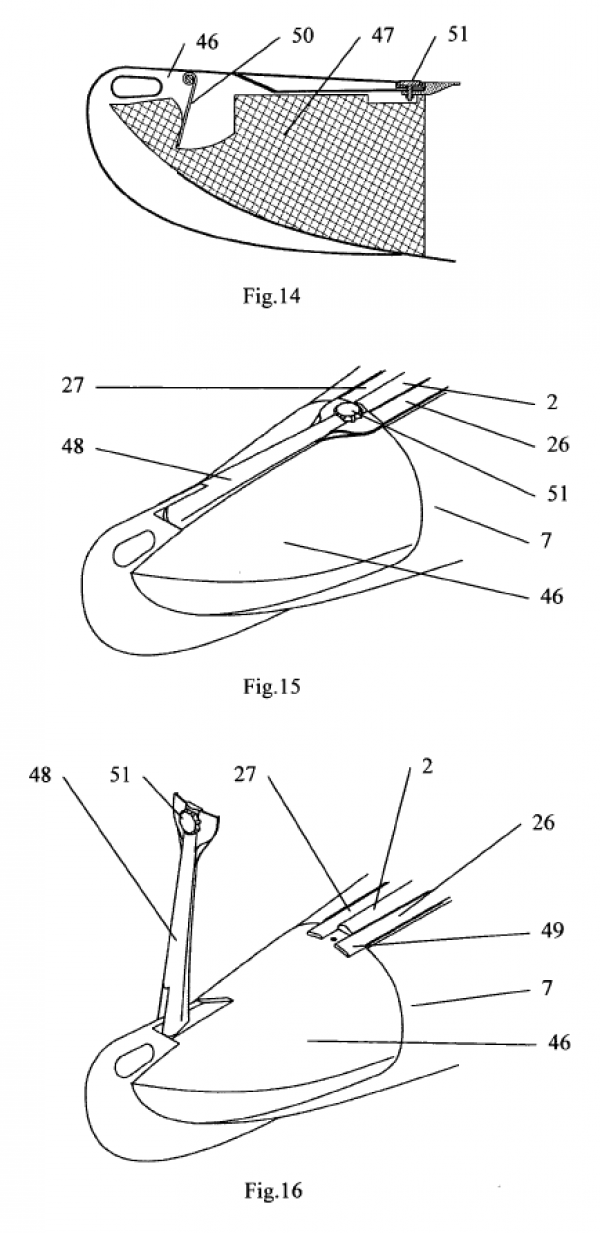

Fig. 14 shows a cross-section of the bow (stern) of the folding kayak with an outer casing and plug; Fig. 15 is a 3-D view of the bow (stern) of the folding kayak with fixed hinged clamping lever;

Fig. 16 is a 3-D view of the bow (stern) of the folding kayak with elevated hinged clamping lever.

The folding kayak includes bow 1 and stern 2 parts of a deck (Fig.l) produced with front 3 and rear 4 portions of a coaming, respectively; side portions 5 and 6 of the coaming, a hull 7, formed by flexible shell 8 (Fig.2), seat 9 of a kayaker, bow 10 and stern 11 sealing joints for the hull 7 cavity isolation.

The side portions 5 and 6 of the coaming are tightly joined with the front 3 and rear 4 portions of the coaming thereby forming a cockpit 12.

The flexible shell 8 edges are fixed along side edges 13 of the bow 1 and stern 2 parts of the deck and along the side portions 5 and 6 of the coaming.

The flexible shell 8 is the main detail of the folding kayak. Its edges 14 and 15 have smooth form and a row of holes 16 alongside. The flexible shell 8 has cut-outs in its bow 17 and stern 18 parts. The flexible shell 8 broadens smoothly from the bow part 17 towards the centre and then tapers smoothly towards the stern part 18. The flexible shell 8 has little double curvature, i.e. longitudinal and transverse curvature, but due to the smooth edges 14 and 15 without any shoulders and extensions, it can be rolled up easily. While rolling up the flexible shell 8 deformation restricts to uniformly spread, smooth (with no folds) bend. Tension or compression is insignificant which makes it possible to use homogeneous semirigid material without flexible insertions for production of the flexible shell 8 which facilitates the design and enhances strength and rigidity of the hull.

There is disposed inner flexible skin 19 within the hull 7 in the cockpit zone 12 (Fig. 3). The opposite sides of the inner flexible skin are tightened at the side portions 5, 6 of the coaming. In the special embodiment the inner flexible skin 19 can be made as an integral unit with the side portions 5,6 of the coaming.

The inner flexible skin 19 serves to reinforce the folding kayak structure in the cockpit zone 12, i.e. in the seat of the kayak's occupant where the structure is subjected to ultimate stresses. The inner flexible skin 19 can also be rolled up but in the transverse direction, i.e. parallel to the side portions 5,6 of the coaming. The flexible shell 8 of the hull 7 and the inner flexible skin 19 can be rolled up one into the other. It is preferable for them to have approximately equal width.

The bow 1 and stern 2 parts of the deck along the side edges 13 and side portions 5, 6 of the coaming are made with conjugated grooves 20 alongside (Fig. 4, Fig. 5, Fig. 6) where the edges 14 and 15 of the hull's 7 flexible shell 8 fit into. Holes 21 are made transverse to the grooves 20 in the bow 1 and stern 2 parts of the deck and in the side portions 5, 6 of the coaming (Fig.4). The hole location aligns with that of the holes 16 on the edges 14 and 15 of the flexible shell 8.

Into the united holes 16 and 21 there are inserted clamping elements 22, 23, 24, 25 (Figs 5-9) fixing the flexible shell 8 of the hull 7 at the bow 1 and stern 2 parts of the deck and side portions 5, 6 of the coaming, situated on two flexible bands 26 and 27 (Fig.1 ) extending on one side of each band (Fig. 7).

The clamping elements 22 and 23 are produced as L-shaped extensions, the ends 28 of which are parallel to each flexible band 26, 27 and are directed towards its centre (Figs 8,9).The flexible bands 26 and 27 have arc-shaped end clamping elements 24 and 25 at their ends having their concave parts facing towards the L-shaped clamping elements 22 and 23.

The flexible bands 26 and 27 are of equal structure and are made in the form of flattened tube of rubber or polyurethane (Fig. 10). The clamping elements 22 and 23 are tightly fixed at plates 29 (Fig. 8) or are made as an integral unit with the plates 29. The plates 29 are located within the flexible bands 26 and 27, whereas the clamping elements 22 and 23 extend outwards. The arc-shaped end clamping elements 24 and 25 are made likewise, but their plates 30 have the adjacent L-shaped clamping elements 22 and 23 fixed on them as well (Fig.9).

Outer parts of the side edges 13 of the bow 1 and stern 2 parts of the deck and side portions 5 and 6 of the coaming can be provided with conjugated indentations 31 (Fig.4) alongside for the flexible bands 26 and 27 location.

In the course of assembling the L-shaped clamping elements 22 and 23 are inserted serially one by one with folding of the correspondent flexible band 26 or 27 starting from its centre into the united holes 16 and 21, as shown in Fig. 11. Distance between each flexible band 26 or 27 and the ends 28 of the L-shaped clamping elements 22 and 23 parallel to them is a bit less than thickness of the bow 1 and stern 2 parts of the deck and side portions 5, 6 of the coaming what provides tight and durable connection in the indentation zone 31 by turning of the L-shaped clamping elements 22 and 23 with their ends 28 parallel to the indentation surface 31. Hereby every following adjusted L-shaped clamping element 22 or 23 prevents the former from withdrawal since the flexible bands 26 and 27 are sunk with certain tension due to that the holes 16 and 21 pitch exceeds the L-shaped clamping elements 22 and 23 pitch on the flexible bands 26 and 27. The arc-shaped end clamping elements 24 and 25 placed at the ends of the flexible bands 26 and 27 dig easily in the outermost holes 21 of the bow 1 and stern 2 parts of the deck since their bend radius corresponds to the distance between each of them and the adjacent L-shaped clamping element 22 or 23 situated on the same plate 30.

Each bow 1 and stern 2 part of the deck is made out of two coupled parts 32 and 33 (Fig.4) which overlap to secure water tightness. Herewith the bow 1 and stern 2 parts of the deck are made with united holes 34 and 35 at the lap length. The L-shaped clamping elements 22 and 23 fit into the united holes 34 and 35 what provides durable connection of the parts 32 and 33 of the bow 1 and stern 2 parts of the deck. The bow 1 and stern 2 parts of the deck abut likewise with the side portions 5 and 6 of the coaming which have extensions 36 (Fig.12) fitting into the holes of the front 3 and rear portions 4 of the coaming.

The inner flexible skin 19 is made with two reinforcing longitudinal elements 37 and 38 placed along the hull 7 at its bottom. Stringers 39, 40, 41 and 42 are located within the hull 7 and at its bottom. The stringers are joined telescopically in order to be extended with the reinforcing longitudinal elements 37 and 38 of the inner flexible skin 19. The reinforcing longitudinal elements 37 and 38 are formed by Ω-shaped folds on the inner flexible skin 19. The stingers 39, 40, 41 and 42 have the analogue cross-section. They are molded of thermoplastic polymer material. The reinforcing longitudinal elements 37 and 38 as well as the stringers 39, 40, 41 and 42 heighten longitudinal rigidity of the folding kayak design. Due to the design peculiarities described above the reinforcing longitudinal elements 37 and 38 as well as the stringers 39, 40, 41 and 42 do not prevent the inner flexible skin 19 from rolling up.

The seat 9 of the kayak's occupant is made with hinged backrest 43 (Fig. 1). The seat 9 is fixed at the reinforcing longitudinal elements 37 and 38, whereas the backrest 43 is fixed on the side portions 5 and 6 of the coaming what contributes to more stable design of the folding kayak in the vertical direction. Cut-outs of the seat 9 (not shown in the drawings) are put on the reinforcing longitudinal elements 37 and 38. The seat 9 is retained due to elastic deformation. Extra fixing rods prevent the seat 9 from longitudinal shift. The fixing rods dig into small holes (not shown in the drawings) in the reinforcing longitudinal elements 37 and 38.

Foot rest 44 is fixed to the stingers 39 and 40 in the bow 1 part of the deck like the seat 9 (Fig.13). Pillar 45 is adjusted between the foot rest 44 and the bow part 1 of the deck in order to increase rigidity of the folding kayak design in the vertical direction.

Each bow 10 and stern 11 sealing joint is made in the form of an outer casing 46 and a plug 47 situated within (Fig.14). The outer casing 46 has a hinged clamping lever 48 (Figs 15, 16) to attach ends 49 of the flexible bands 26 and 27 and to connect the outer casing 46 with the corresponding bow 1 or stern 2 part of the deck. The hinged clamping lever 48 is linked to a pusher 50 located within the outer casing 46 (Fig. 14). The pusher 50 is made in the form of a spring to push the plug 47 into the outer casing 46.

The outer casings 46 comprise the flexible shell 8 of the hull 7 from outside which is abutted to inner surface of the outer casing 46 by the plug 47 what provides water tightness. The outer casings 46 overlap the corresponding bow 1 or stern 2 part of the deck. Herewith the arc-shaped end elements 24 and 25 fit into the holes (not shown in the drawings) in the outer casings 46, the holes 16 in the flexible shell 8 and the holes 21 united with them in the bow 1 or stern 2 part of the deck, respectively, fixing the outer casings 46. The hinged clamping lever 48 is fixed by a screw 51 on the bow 1 or stern 2 part of the deck, respectively, fastening the ends 49 of the flexible bands 26 and 27.

The stringers 39, 40, 41 and 42 ends are fixed on the corresponding plugs 47. The flexible shell 8 of the hull 7, inner flexible skin 19, outer casings 46, plugs 47, foot rest 44, bow 1 and stern 2 parts of the deck and side portions 5 and

6 of the coaming are made of thermoplastic polymer material. There may be used polyethylene, polypropylene, ABS-resin. The flexible shell 8 of the hull 7 and the inner flexible skin 19 are 1-2 mm thick and are made of sheet polyethylene, polypropylene or ABS-resin. The stringers 39, 40, 41 and 42 can be molded of thermoplastic polymer material. The flexible bands 26 and 27 can be made of rubber and polyurethane. In test model there were used the flexible bands 26 and 27 made of polyvinylchloride. The plugs 47 and foot rest 44 are produced by filling the inner cavities with polyurethane foam. There can be utilized other foam materials. For the pillar 45 there can be used duralumin tube. The folding kayak details are produced in accordance with methods known for the applied material taking into account details configuration.

Assembling of the present construction is as follows: Put the inner flexible skin 19 into the unrolled flexible shell 8. Extend the stringers 39, 40, 41, 42. Fix the seat 9 on the longitudinal elements 37 and 38. Fix the foot rest 44 at the stringers 39 and 40. Fix the plugs 47 at the ends of the stringers 39, 40, 41 and 42. Fix the backrest 43 at the side portions 5 and 6 of the coaming.

Place the bow 1 and stern 2 parts of the deck atop, join them with the side portions 5 and 6 of the coaming. Fit the edges 14 and 15 of the flexible shell 8 into the grooves 20 uniting the holes 16 of the flexible shell 8 with the holes 21. Then adjust the flexible bands 26 and 27, therewith inserting the L-shaped clamping elements 22 and 23 into the united holes 16 and 21 as described above. At this stage connect the bow 1 and stern 2 parts of the deck with the side portions 5 and 6 of the coaming. Join serially the parts 32 and 33, respectively, of the bow 1 and stern 2 parts of the deck. Then adjust the outer casings 46 and fasten them by the arc-shaped end clamping elements 24 and 25, as described above.

Then pull down the hinged clamping levers 48 which push the plugs 47 tightly into the outer casings 46. Thereby the flexible shell 8 is wedged between inner surface of the outer casing 46 and the plug 47. The clamping levers 48 are attached by the screws 51 , thereby abutting and fixing the ends 49 of the flexible bands 26 and 27.

The construction is dismantled in reverse order.

The foregoing represents the presently preferred form of a folding kayak which is the best embodiment to the priority date of the invention. Other embodiments complying with the scope of exclusive rights to the use of the invention are also possible.

Claims

1. A folding kayak containing bow and stern parts of a deck made with front and rear portions of a coaming, respectively; side portions of the coaming rigidly united with the front and rear portions of the coaming of the bow and stern parts of the deck forming a cockpit; a hull shaped by flexible shell which edges are fastened along side edges of the bow and stern parts of the deck and alongside on the side portions of the coaming; at least, one seat for a kayk's occupant; bow and stern sealing joints for the hull cavity isolation; and inner flexible skin disposed within the hull, in the cockpit zone, at least, with its opposite sides secured to the side portions of the coaming.

2. A folding kayak as in claim 1, wherein the inner flexible skin is made, at least, with two reinforcing longitudinal elements which are located along the hull at its bottom part.

3. A folding kayak as in claim 2, wherein within the hull at its bottom part there are positioned stringers telescopically joined with the reinforcing elements of the inner flexible skin.

4. A folding kayak as in claim 2, wherein the seat is made with hinged backrest; the seat is fixed on the reinforcing longitudinal elements of the inner flexible skin whereas the backrest is fixed on the side portions of the coaming. 5. A folding kayak according to claim 2 characterized by a foot rest, fixed at the stringers in the bow part of the deck; and pillar linked to the foot rest and bow part of the deck.

6. A folding kayak as in claim 1 , wherein the side edges of the bow and stern parts of the deck and side portions of the coaming are made with conjugated grooves alongside where the hull's flexible shell edges fit into.

7. A folding kayak as in claim 6, wherein the bow and stern parts of the deck and side portions of the coaming have holes located transversely to the grooves, said holes coincide with those made at lateral edges of the hull's flexible shell. In this case clamping elements fixing the hull's flexible shell fit into the holes.

8. A folding kayak according to claim 7 provided with two flexible bands each of them containing clamping elements fixing the hull's sheet material on one side.

9. A folding kayak as in claim 8, wherein the clamping elements fixing the hull's flexible shell are produced as L-shaped extensions, the ends of which are parallel to the flexible band and are directed towards its centre.

10. A folding kayak as in claim 9, wherein the flexible bands have arc-shaped end clamping elements at their ends, located on the same side of each band with the clamping elements in form of L-shaped extensions having their concave parts facing inwards.

11. A folding kayak as in claim 8, wherein the side edges of the bow and stern parts of the deck and side portions of the coaming are provided with conjugated indentations alongside for the flexible bands location.

12. A folding kayak as in claim 1, wherein each bow and stern sealing joint is made in the form of outer casing and a plug positioned within, herewith the outer casing has a hinged clamping lever in order to fix the flexible bands ends and to attach the outer casing to the bow or stern parts of the deck.

13. A folding kayak as in claim 12, wherein the hinged clamping lever is connected with a pusher situated within the outer casing to push the plug inwards. 14. A folding kayak as in claim 1, wherein each bow and stern part of the deck is made of, at least, two coupled parts.

15. A folding kayak as in claim 1, wherein the side portions of the coaming are made as an integral unit with the inner flexible skin.

16. A folding kayak as in claim 1, wherein the hull's flexible shell and inner flexible skin, outer casings, plugs, bow and stern parts of the deck, as well as side portions of the coaming are made of thermoplastic polymer material.

17. A folding kayak as in claim 1, wherein the hull's flexible shell and inner flexible skin are 1-2 mm thick and are made of sheet polyethylene, or polypropylene or ABS-resin. ,

18. A folding kayak as in claim 1, wherein the reinforcing longitudinal elements are made in the form of hollow elements formed of inner flexible skin parts, the stringers are molded of thermoplastic polymer material.

19. A folding kayak as in claim 8, wherein the flexible bands are produced in the form of flattened tube made of rubber or polyurethane.

Abstract

The objective of the invention is to propose a simple design of a folding kayak adaptable to streamlined production and which can be easily folded into a compact pack. The folding kayak includes bow (1) and stern (2) parts of a deck produced with front (3) and rear (4) portions of a coaming, respectively; side portions (5, 6) of the coaming, a hull (7), formed by flexible shell (8), seat (9) of a kayaker, bow (10) and stern (11) sealing joints for the hull (7) cavity isolation. The side portions (5, 6) of the coaming are tightly joined with the front (3) and rear (4) portions of the coaming thereby forming a cockpit (12). The flexible shell (8) edges are fixed along side edges (13) of the bow (1) and stern (2) parts of the deck and along the side portions (5, 6) of the coaming. There is disposed inner flexible skin within the hull (7) in the cockpit zone (12) with its opposite sides secured to the side portions (5, 6) of the coaming.

30+

30+