Номер международной заявки: PCT/RU2008/000423

Заявитель: Общество с ограниченной ответственностью «ВДС»

Авторы: МАНАШЕРОВ Тамази Омарович, МАТЕЛО Светлана Константиновна, ГРОССЕР Александр Владимирович

Международная патентная классификация (МПК): A61K 8/42 (2006.01), A61K 8/02 (2006.01), A61K 8/38 (2006.01), A61Q 11/02 (2006.01)

Дата международной подачи: 01.07.2008

Дата международной публикации: 29.01.2009

Приоритет от 25.07.2007 по заявке EA 200701554Tooth paste

Field of applicationThe invention relates to stomatology and perfume industry, to tooth-paste in particular.

Background of inventionThere is known tooth paste which comprises glycerine, propyleneglycol, silica, peroxide carbamide, gelling agents based on processed starch, aluminium oxide, surface-active components, anti-carious additive – sodium monofluorphosphate, pH value regulators, papain, polyacrylic acid, sodium saccharinate, mint perfume (US B2 No6511654, IPC 7 A61 K7/16, 2003).

Peroxide carbamide contained in the known tooth-paste provides efficient teeth bleaching, along with residual moisture which always remains in the paste prepared in accordance with known techniques it breaks up with the following formation of hydrogen peroxide and urea. Later on there takes place a reaction with formation of active oxygen forms: H-O-O-, -O-O-, -O-, and О2, NH3, Н2О and СО2. Thereby active oxygen concentration reduces during long-term storage whereas natural confined gassing of tooth-paste package results in its bloat or often in crippling.

Moreover in tooth-paste preparation of the known formulation, mix should be heated to the temperature not lower than 87 ºС (87-140 ºС) for complete swelling of starch derivatives that leads to increase of energy costs on production.

Substance of inventionThe major focus of the present invention is on elaboration of the tooth-paste endowed with bleaching effect due to having peroxide compound in its formulation. There must be ensured long-term storage of the prepacked tooth-paste without its utility loss. It should be admitted to prepare tooth-paste without heating it to temperatures higher that 60 ºС.

The given task is being accomplished by preparing tooth-paste which involves active components with anhydrous base inclusively as well as active components such as peroxide carbamide in quantity of 8.0-12.0 wt % and micronized polyethylene wax as abrasive filler and peroxide stabilizer in amount of 10.0-30.0 wt %.

Micronized polyethylene wax is formed by spherical particles ranging from 5 to 10 micron in diameter with smooth and even surface, which endows it with nice cleansing and insignificant abrasive properties aiding to exclude traumatizing of enamel surface. It is also known that stabilizing effect on peroxides is connected with adsorptive phenomena of additives. (Hydrogen peroxide and peroxide compounds. Edited by prof. M.E. Pozina, GNTIKHL, 1951, p. 268). Micronized polyethylene wax plays part of such additive in the developed formulation since it has protective and coating ability due to its high developed hydrophobic surface. It stabilizes peroxide thereby securing formulation stability. This factor renders it possible to avoid unit package (polyethylene or aluminium tube) bloating at room temperature.

In the preferred option of realization tooth-paste contains calcium glycerophosphate as additional active component; and xylitol, aluminium oxide, PEG-40 hydrogenated castor oil, alkylamidobetaine mint perfume in the quality of inert components; propyleneglycol, polyacrylic acid, tromethamine and glycerine as anhydrous base at the following ratio of the components numbered, wt %:

Calcium glycerophosphate 0,10 – 0,25

Xylitol 2,0 – 3,0

Aluminium oxide 2,0 – 8,0

PEG-40 hydrogenated castor oil 0,8 – 1,2

Alkylamidobetaine 0,8 – 1,2

Mint perfume 0,3 – 0,7

Propyleneglycol 20,0 – 25,0

Polyacrylic acid 0,6 – 2,0

Tromethamine 0,2 – 0,6

Glycerine Up to 100

In the preferred option including peroxide carbamide and micronized polyethylene wax, it is not required to heat paste to temperatures higher than 60 ºС since the formulation prepared does not involve components which require substantial mass heating in order to be brought to suspension condition. Therefore, energy costs on final product manufacture decrease.

As mint perfume there is used perfume based on purified mint oils and its mix with methylcalicilate. It is inappropriate to use other perfume modifications as there is high probability of perfume components oxidation resulting in adverse change in fragrance.

Realization of inventionHereinafter in table 1 there are illustrated examples of the specific formulations and described techniques of tooth-paste preparation in accordance with the present invention.

Tooth-pastes preparation in compliance with the developed formula is carried out in the following way:

- Weigh glycerine required, add polyethyleneglycol and xylitol; mix to formation of homogeneous mass;

- Add slowly polyacrylic acid at a high mixer rotation speed (800-900 rpm) and mix to equal distribution of the latter, mix is heated to 50-55 ºС;

- Switch off the mixer and allow the mix for 30-40 minutes till swelling of polyacrylic acid;

- Switch on the mixer and mix the formulation till formation of viscous homogeneous gel;

- Add calcium glycerophosphate, aluminium oxide and micronized polyethylene wax into the gel obtained, mix till formation of homogeneous mass, cool it down to 20-25 ºС; if required homogenize and degas the mix;

- Add slowly peroxide carbamide and mix till formation of homogeneous mass;

- Add tromethamine and mix till formation of homogeneous mass

- Add alkylamidobetaine and mix till formation of homogeneous mass;

- Feed PEG-40 hydrogenated castor oil earlier prepared, mint perfume of mint oil and methylcalicilate into the mixer with paste and mix till formation of homogeneous pasty mass.

Technological process described above holds for preparation of either formulations listed in table 1 or other tooth-pastes in compliance with the invention.

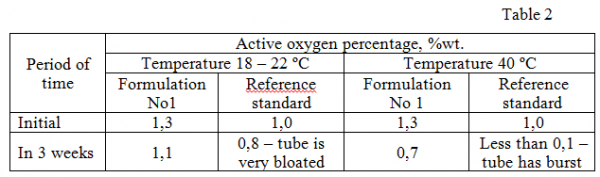

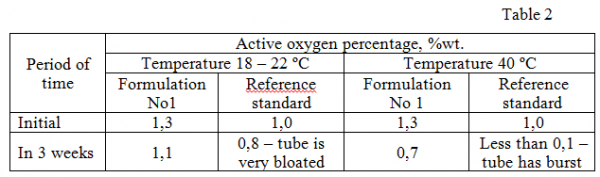

Effectiveness of the tooth paste developed was evaluated by active oxygen content change in formulation No1 (table 1). As reference standard it was used ‘Rembrandt’ tooth-paste, prepared according to the formula in compliance with the analogue described above. (US B2 No6511654, IPC 7 A61K7/16, 2003).

Active oxygen content was measured at initial state of formulations and on three-week storage at room temperature of 18-22 ºС and at elevated temperature of 40 ºС. Estimation of active oxygen content was carried out iodimetrically.

Analysis results are described in table 2.

On the basis of the data listed in table 2 we come to conclusion that the formulation represented ensures peroxide compound stabilization and excludes unit package bloat at room temperature.

Example of administered use of formulation No2 (Table 1):

Patient X, 26 years of age, has complained on unsatisfactory cosmetic teeth appearance.

During the first examination it has been established:

Teeth colour according to Vita scale – D4, gloss is not enough.

It has been administered to the patient a four-week course on condition that she should use only the indicated tooth-paste every day for 2-3 minutes instead of usual tooth-paste.

The next examination has been carried out in 4 weeks. Teeth colour according to Vita scale – D4, gloss has become more intense. There are no complaints.

Thus, dental enamel has whitened by 4 tones.

Claims

1. Tooth paste composition involves inert components including anhydrous base as well as active components such as peroxide carbamide in amount of 8.0-12.0 wt % and micronized polyethylene wax in the function of abrasive filler and peroxide stabilizer in quantity of 10.0-30.0 wt %.

2. Tooth paste according to point 1 containing calcium glycerophosphate as additional active components; and xylitol, aluminium oxide, PEG-40 hydrogenated castor oil, alkylamidobetaine, mint perfume as inert components; propyleneglycol, polyacrylic acid, tromethamine and glycerine as anhydrous base at the following ratio of the components numbered, wt %:

Calcium glycerophosphate 0,10 – 0,25

Xylitol 2,0 – 3,0

Aluminium oxide 2,0 – 8,0

PEG-40 hydrogenated castor oil 0,8 – 1,2

Alkylamidobetaine 0,8 – 1,2

Mint perfume 0,3 – 0,7

Propyleneglycol 20,0 – 25,0

Polyacrylic acid 0,6 – 2,0

Tromethamine 0,2 – 0,6

Glycerine Up to 100

3. Tooth paste according to point 2 is characterized by containing mint perfume based on purified mint oils or perfume mix based on purified mint oils with methylcalicilate.

Abstract

The invention refers to stomatology and perfume industry, to tooth paste in particular. Tooth paste composition involves inert components including anhydrous base as well as active components such as peroxide carbamide in amount of 8.0-12.0 wt % and micronized polyethylene wax in the function of abrasive filler and peroxide stabilizer in quantity of 10.0-30.0 wt %.

30+

30+